Inflatable Brace

3.0 Videos

Inflation/Deflation Explanation

External User Interface

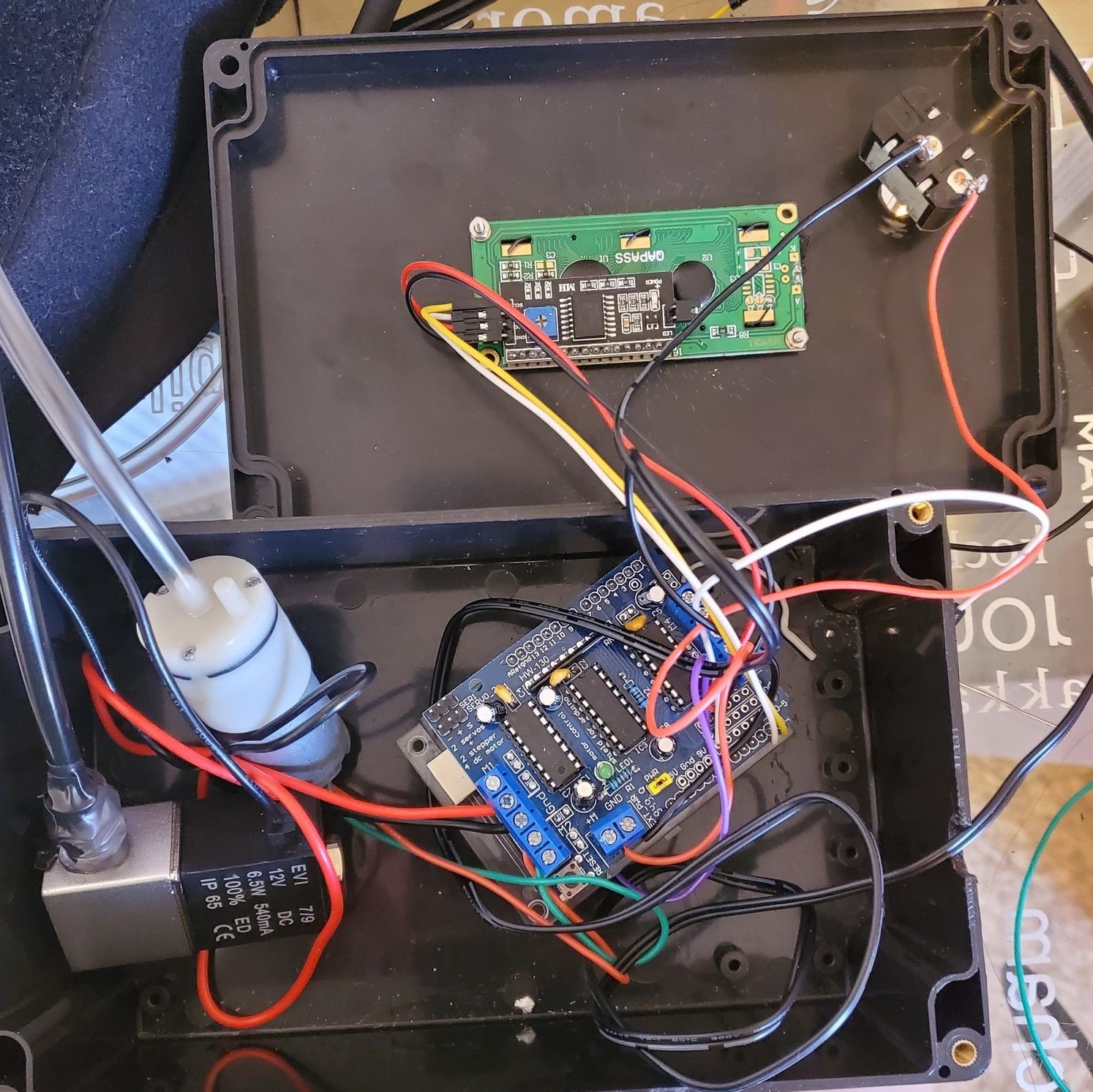

Internal Wiring

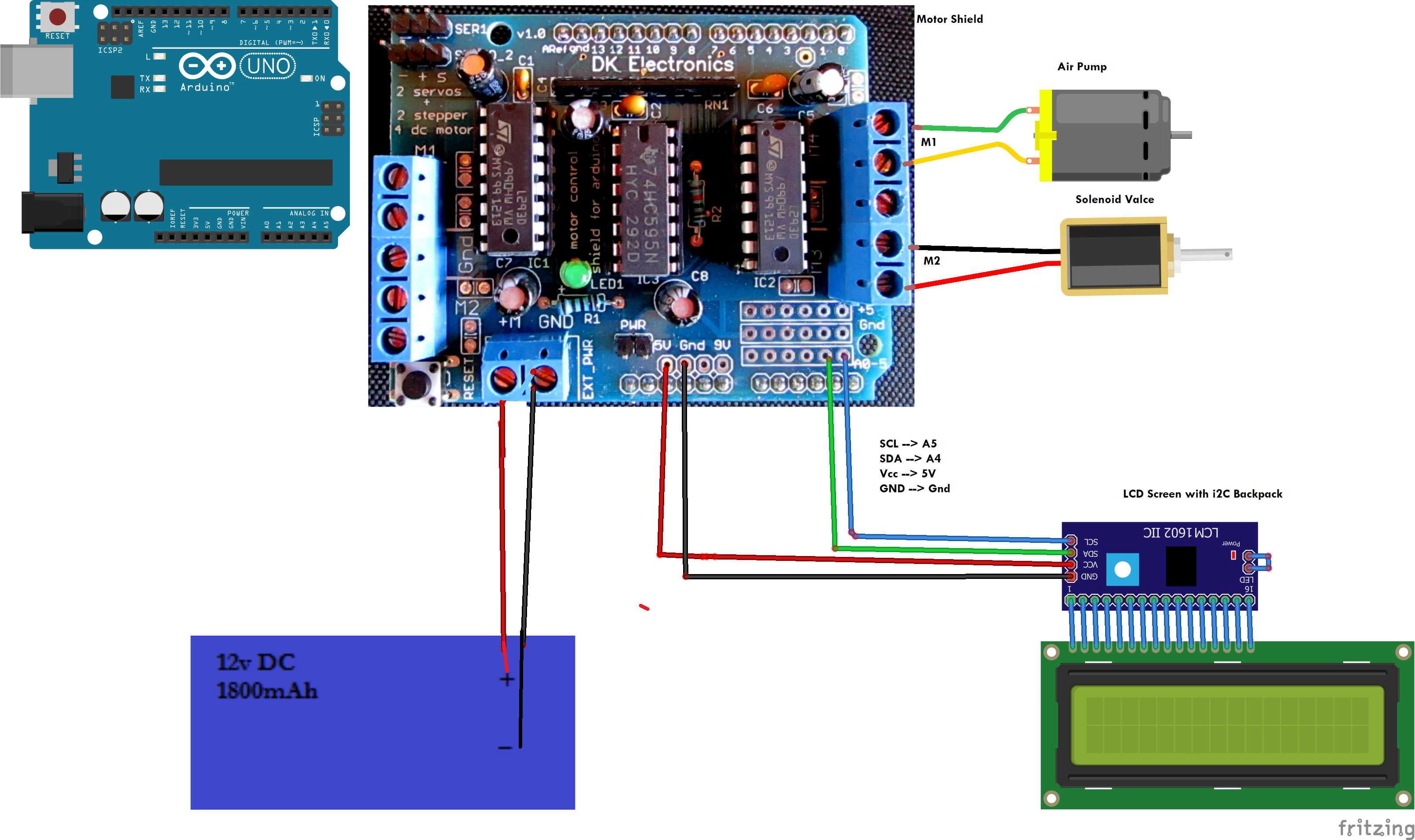

Circuit Diagram

#include //needed to drive motor

#include //needed for circuits

#include //needed w LCD i2C Library

AF_DCMotor pump(2, MOTOR12_64KHZ); // create motor #1, 64KHz pwm for greater inflation power

AF_DCMotor vacuum(1, MOTOR12_8KHZ); // create motor #2, 8KHz pwm

LiquidCrystal_I2C lcd(0x27, 16, 2);

//LCDvariablename(address [use find_lcd_screen_address program to locate], 16x2 characters)

void setup() {

Serial.begin(9600); //begin serial communication (9600 for LCD)

lcd.begin();//Initializing display

lcd.backlight();//To Power ON the back light NOTE: if backlight doesn't turn on,

// ensure power jumper is attached

lcd.setCursor(0,0); //use first row

lcd.print(" WELCOME "); //print mode

pump.setSpeed(255); // Set motor 1 to maximum speed

vacuum.setSpeed(200); // Set solenoid valve to maximum speed

delay(100); //delay

}

//The following loop runs forever

void loop() {

lcd.clear();

vacuum.run(FORWARD); //release the solenoid valve

lcd.setCursor(0,0); //use first row

lcd.print(" INFLATING "); ////print state of device (inflating)

pump.run(FORWARD); // turn on pump

delay(8000); //run for 5000ms

pump.run(RELEASE); //detach the motor to conserve power

lcd.clear(); //clear the screen

lcd.setCursor(0,0); //use first row

lcd.print(" HOLDING "); //print state of device (pausing on inflation)

delay(2000); //delay 5000ms

lcd.clear(); //clear the screen

lcd.setCursor(0,0); //use first row

lcd.print(" DEFLATING "); //print state of device (deflating)

vacuum.run(BACKWARD); //reverse polarity on solenoid valve (since it is normally closed,

//ground will keep it closed)

delay(1000); //allow 1s to release pressure

vacuum.run(FORWARD); //release the solenoid valve

delay(500); //delay .5 second

}