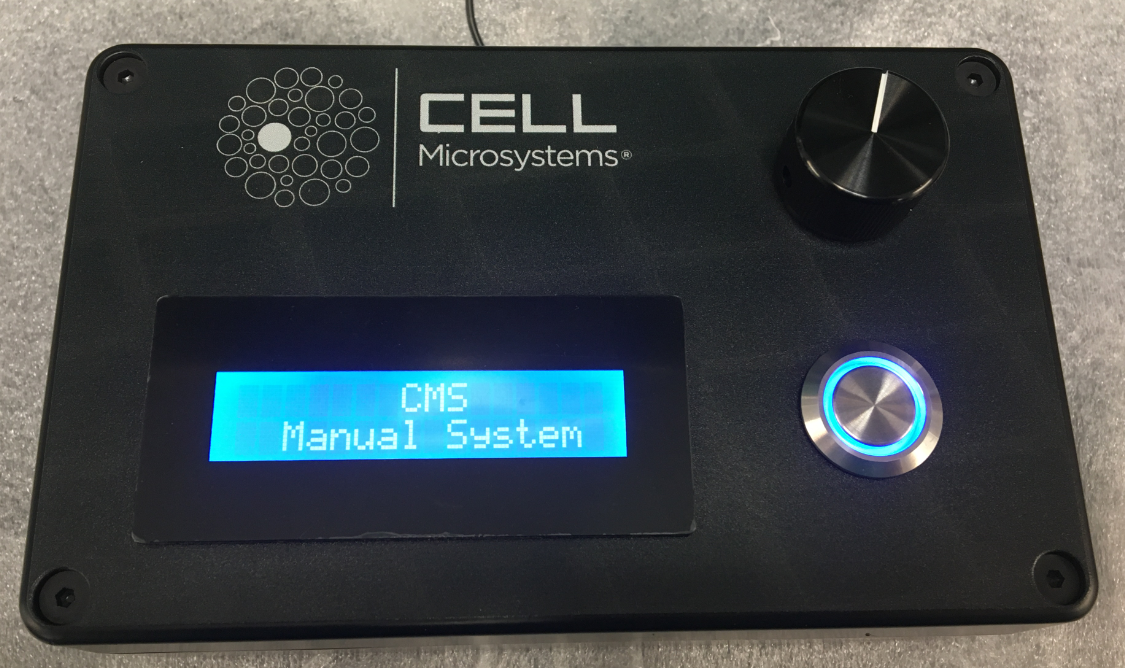

CMS Manual System

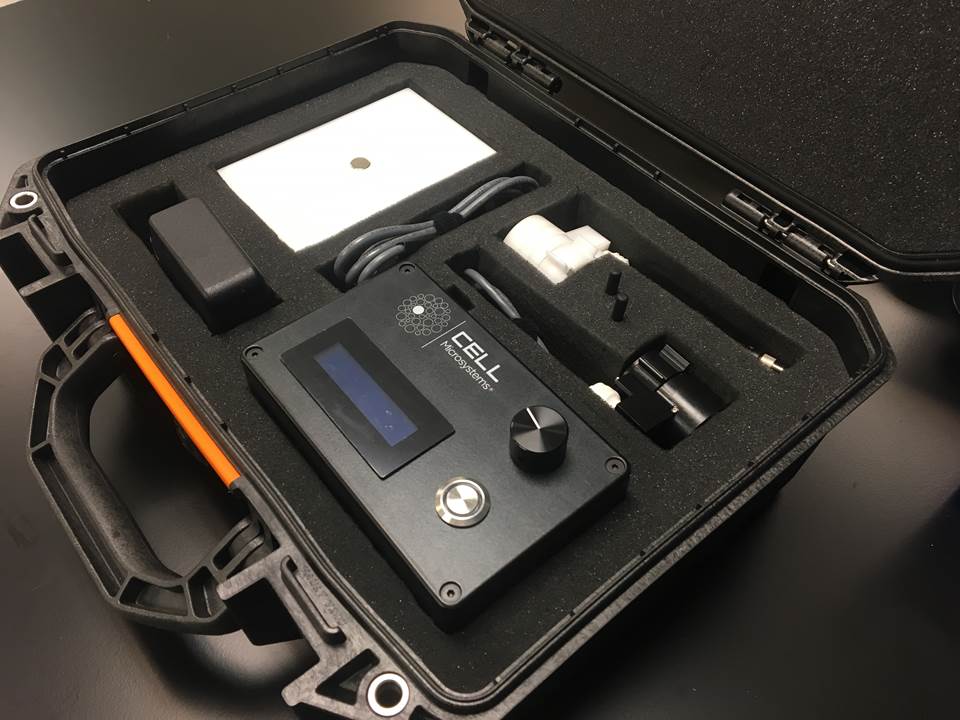

CMS Manual System in Case

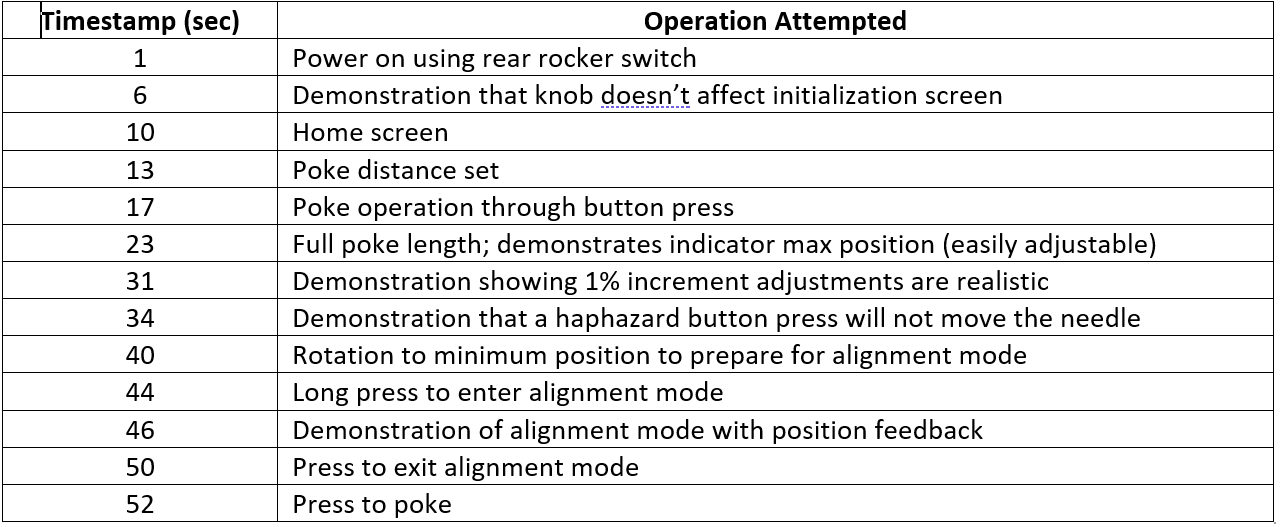

3.0 Videos

System Operation

Table Explaining Functionality

#include //needed to drive motor

#include //needed for circuits

#include //needed w LCD i2C Library

AF_Stepper motor(20,1); //20 steps/rev w motor; Motor connected to port 1 (M1/M2)

LiquidCrystal_I2C lcd(0x27, 16, 2);

//LCDvariablename(address [use find_lcd_screen_address program to locate], 16x2 characters)

int sensorPin = A1; //select the input pin for the potentiometer

int button = A2; //select the pin for the button

int sensorValue = 0; //Initialize variable to store the value coming from the sensor

int homePos = 700; //number of steps down to home position; overshot to ensure fully 0

int state; //Initialize variable to store value from button

int motorMove = 0; //state of travel mode

int travelSteps = 0; //number of steps set by pot

int travelDist = 0; //number of steps to travel

int travelPercent = 0; //percent to display on LCD screen (1-100%)

int align = 0; //Initialize variable to check if in alignment mode

int delta = 0; //Initialize variable for movement in alignment mode

int welcome = 1; //Initialize variable for welcome screen state

int reading; // the current reading from the input pin

int check = 0;

void welcomeScreen() {

motor.step(homePos, BACKWARD, SINGLE); //travel motor to 0 position

while (welcome == 1){ //repeat while welcome = 1 is true

lcd.setCursor(0,0); //use first row

lcd.print(" CMS "); //welcome screen

lcd.setCursor(0,1); //use second row

lcd.print(" Manual System "); //welcome screen

reading = digitalRead(button); //read state of button (high or low)

if ((reading) == HIGH) { //While the button is pressed

while ((analogRead(sensorPin) < 5) == 1) { //loop while the potentiometer is set below 5 (for safety)

delay(100); //debounce button

reading = digitalRead(button); //check button state to ensure it has been released.

//This allows for the user to press it for any period of time

if (reading == LOW){ //if the button is not pressed any longer

welcome = 0; //set welcome screen to 0 so it never shows up again

align = 1; //allow alignment mode

delay(100); //debounce the button (ms)

Alignment(); //enter alignment mode (always entered upon first boot up for safety)

}

}

delay(100); //debounce the button

}

}

}

void CheckHold() { //check if button has been pressed

motor.release(); //release motor when not in alignment or travel

delay(100); //debounce the button

reading = digitalRead(button); //check state of button (HIGH or LOW)

if (reading == HIGH) { //if the button is pressed

check = 1; //if button has been pressed, loop until it is not pressed anymore

while (check == 1) {

if ((analogRead(sensorPin) < 5) == 1) { //If the potentiometer is set below 5..

delay(100);

reading = digitalRead(button); //recheck button

if (reading == LOW){ //if it has been released

motorMove = 0; //disable travel mode

align = 1; //allow alignment mode

check = 0; //exit check loop

delay(100); //debounce button

Alignment(); //enter alignment mode.

}

}

else { //if pot is greater than 5

delay(100); //debounce

reading = digitalRead(button); //read button

if (reading == LOW){ //if button is released

motorMove = 1; //enable travel mode

align = 0; //disable alignment mode

check = 0; //exit check loop

delay(100); //debounce

NeedleRelease(); //enter travel mode

}

}

delay(100); //debounce the button

}

}

}

void NeedleRelease() {

align = 0; //disable alignment mode

lcd.clear(); //clear screen

lcd.setCursor(0,0); //use first row

lcd.print(" Traveling "); //centered "traveling" state

lcd.setCursor(0,1); //use second row

lcd.print(" "); //centering text

lcd.print(travelPercent); //print travel distance (1-100%)

lcd.print("% "); //print travel distance (1-100%)

motor.step(travelSteps, FORWARD, SINGLE); //run motor to the number of steps set by pot

delay(100); //pause 100ms

motor.step(homePos, BACKWARD, SINGLE); //run motor to home (overshot)

delay(500) ; //Must wait 500 ms before next release

lcd.clear(); //clear screen

motor.release(); //Make the motor "float" so that it does not consume power

motorMove = 0; //disable release mode

loop(); //return to home loop

}

void Alignment() {

welcome = 0; //disable welcome screen from now on

delay(100); //delay

lcd.clear(); //clear LCD screen

lcd.setCursor(0,0); //use first row

lcd.print(" Alignment Mode"); //print which mode

sensorValue = analogRead(sensorPin);

//Read the value from the potentiometer - Range can be from 0 - 1023

MOVE = round(sensorValue*0.5);

//Multiply value by 0.5 to make max number of steps 512 (10.24 mm)

motor.step(MOVE, FORWARD, SINGLE);

//Move motor to position set by potentiometer

delay(100); //delay

while (align == 1) {

//While in alignment mode execute the following code:

sensorValue = analogRead(sensorPin); //0-1023

travelPercent = round(sensorValue*.098); //convert potentiometer value to percent

lcd.setCursor(0,1); //use second row

lcd.print(" Distance: "); //print travel distance (1-100%)

lcd.print(travelPercent); //print travel distance (1-100%)

lcd.print("% "); //print travel distance (1-100%)

travelSteps = round(sensorValue*.5); //capping max steps at = 1023/2 = ~512 steps

travelDist = travelSteps - delta; //num steps to travel (checks for change from prvious pot value)

if (travelDist > 4) { //if change is positive & > 4

motor.step(travelDist, FORWARD, SINGLE); //travel difference in steps

delta = travelSteps; //keep track of previous value

}

else if (travelDist < -4) { //if change is negative & > 4

motor.step(abs(travelDist), BACKWARD, SINGLE); //travel difference in steps

delta = travelSteps; //keep track of previous value

}

motor.release(); //Float the motor to save power

delay(10); //small delay

reading = digitalRead(button); //check button state

if (reading == HIGH) { //if the button is pressed

check = 1; //loop until button is low

while (check == 1) { //loop until button is low

delay(100);

reading = digitalRead(button);

if (reading == LOW){ //if button is released

lcd.clear();

lcd.setCursor(0,0); //use second row

lcd.print(" Exiting "); //print mode

lcd.setCursor(0,1); //use second row

lcd.print(" Alignment Mode"); //print mode

motor.step(travelSteps, BACKWARD, SINGLE); //Return the motor to its initial position

lcd.clear(); //clear screen

delay(100); //delay for noise reduction

align = 0; //disable alignment

check = 0; //disable check loop

delay(100); //delay

loop(); //return to home loop

}

delay(100); //debounce the button

}

}

}

}

void setup() {

Serial.begin(9600); //begin serial communication (9600 for LCD)

lcd.begin();//Initializing display

lcd.backlight();//To Power ON the back light NOTE: if backlight doesn't turn on, ensure power jumper is attached

lcd.clear(); //clear screen

motor.setSpeed(1500); //Sets speed in steps per second

pinMode(button, INPUT); //Set the button pin to be an digial input

delay(100); //delay

welcomeScreen(); //upon start up, open welcome screen

}

//The following loop runs forever

void loop() {

welcome = 0; //disable welcome screen

lcd.setCursor(0,0); //use first row

lcd.print("Press button to"); //print travel distance (1-100%)

lcd.setCursor(0,1); //use second row

lcd.print("Align or Release"); //print travel distance (1-100%)

reading = digitalRead(button); //Check the state of the button

if (reading == HIGH){ //if the button is pressed..

CheckHold(); //Run CheckHold() function

}

}