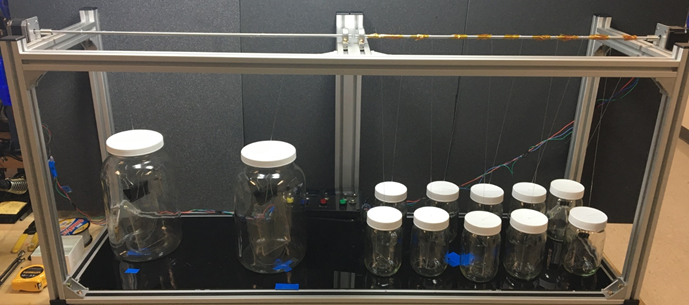

Full Dip Station Set Up

3.0 Videos

Dip Station Demonstration

LCD Screen to Board

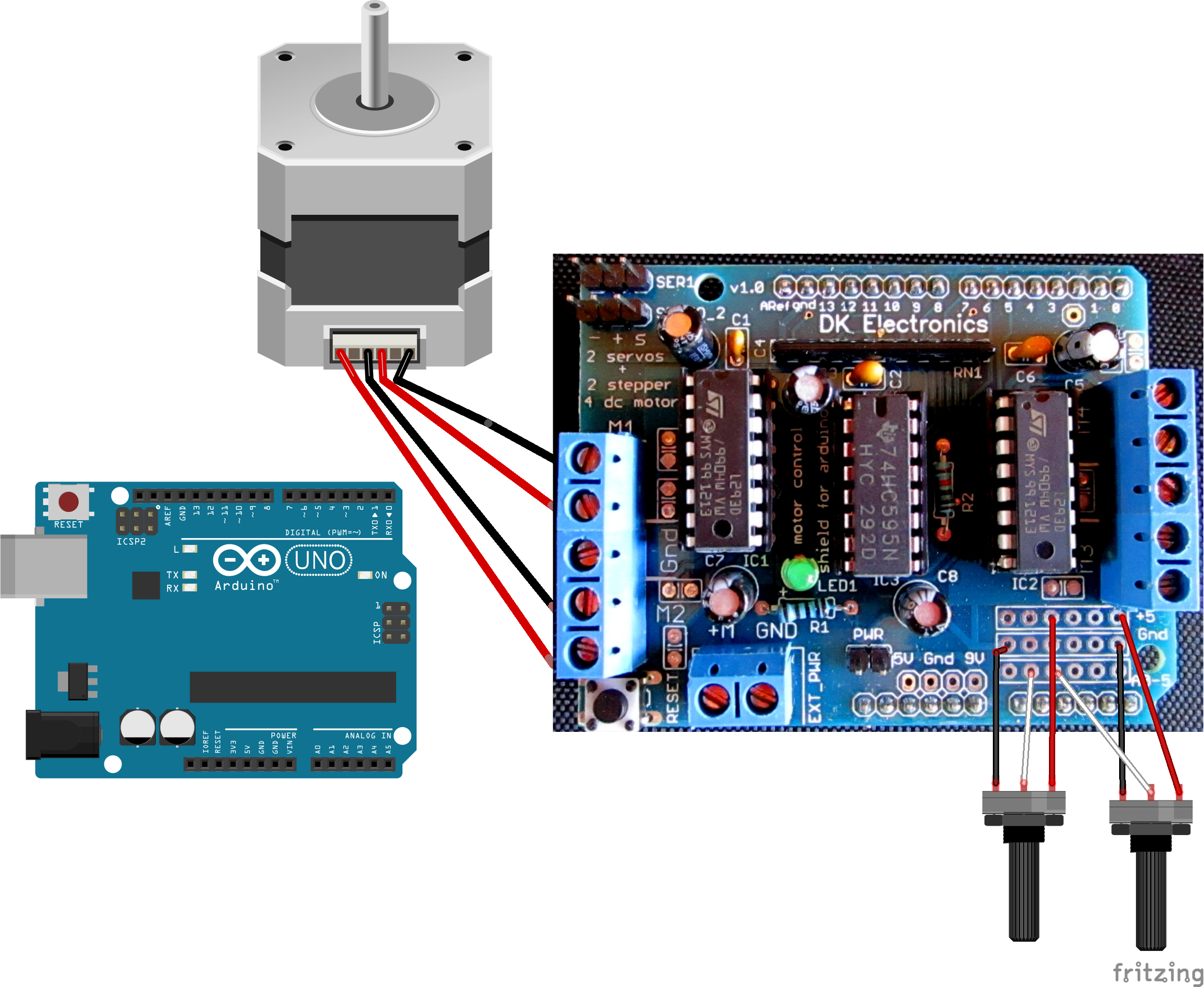

Circuit Diagram II

10K Pot 1 output [Time] --> A1

10K Pot 2 output [Distance] --> A2

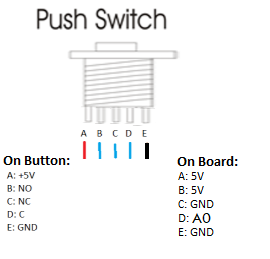

"Start" Button to Board

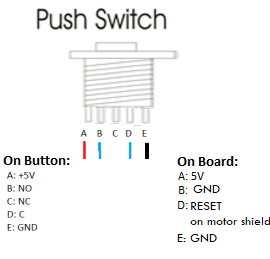

"Reset" Button to Board

#include //needed to drive motor

#include //acceleration library is smoothest

#include //needed for circuits

#include //needed w LCD 12C Library

LiquidCrystal_I2C LCD(0x27, 16, 2); //usual address of LCD Screen with pixels (width, height)IW

AF_Stepper motor1(200,2); //200 steps/rev w motor; Motor connected to port 2 (M3/M4)

void forwardstep() { //wrapping the AFmotor lib for use with accel stepper for forward motion

motor1.onestep(FORWARD, SINGLE);

}

void backwardstep() { //wrapping the AFmotor lib for use with accel stepper for backward motion

motor1.onestep(BACKWARD, SINGLE);

}

AccelStepper motor(forwardstep,backwardstep); //initializing motor as object in accel stepper

int Pot1; //potentiometer 1 (Time: A2 (min))

int Pot2; //potentiometer 2 (Distance: A3 (mm))

int button = A0; //button on analog pin A0

int Time; //Time variable

int RemTime; // Remaining Time

float Dist; // Distance variable (mm)

float mmperRev = 20; //mm in 1 rev of dowel (2*pi*r) r =3.175 (dowel diameter/2)

int numRevs;

void setup()

{

LCD.backlight(); //turn on LCD backlight

Serial.begin(9600); // IW begin serial communication (9600 for LCD)

pinMode(button,INPUT); // IW initialize button as input

LCD.begin();//Initializing display iw

delay(500); // IW delay 500ms

LCD.clear();// IW clear screen

motor.disableOutputs();//disable motor function

delay(500); // delay

}

void loop() // run over and over

{

while (!digitalRead(button)) { //while button NOT pressed (because it is "normally open" button)

motor.disableOutputs();

Pot1 = 1023-analogRead(A1); //// IW finding time from pot 1

int val = 180*(float(Pot1)/1023);// IW finding time

Time = (val-(val%5)+5); // IW finding time

Pot2 = 1023-analogRead(A2);// IW finding dist (A1 on right dip controller/A3 on left dip controller)

Dist = Pot2*0.01*16.49;

// the distance values (mm) displayed on the LCD screen. If you want the dip station to go farther, increase the multipliers here. Current range: up to 160cm.

LCD.clear(); //clear screen

LCD.setCursor(0,0); //1st row 1st column

LCD.print("Time: ");

LCD.print(Time); //print time

LCD.print(" minutes");

LCD.setCursor(0,1); //1st column second row

LCD.print("Dist: "); //print distance

//if (Dist<10.5) {

//LCD.print(0);

//}

LCD.print(Dist,1);

LCD.print(" mm");

delay(100);

}

LCD.clear();

delay(500);

while (digitalRead(button)); //after button has been pressed (5V goes to A0).

LCD.setCursor(0,0);

LCD.print("Remaining Time:"); //print time

long T = millis();

float numRevs = Dist/mmperRev; //total number of revs (total distance/mm per rev)

int numSteps = ceil(numRevs*200); //total number of steps (total revs *200 bc 200 steps/rev)

float seconds = Time*60; //minutes to seconds (total time)

float velocity = numSteps/seconds; //find velocity (steps per second).

motor.setSpeed(velocity); //set speed of motor to this constant velocity value.

motor.enableOutputs();

do { //do while loop. loop exits when remaining time reaches 0.

RemTime = Time-((millis()-T)/60000); //calculate remaining time.

LCD.setCursor(0,1);

LCD.print(RemTime);

LCD.print(" min "); //print remaining time

//motor.setSpeed(steps/second);

motor.runSpeed(); //run the motor at the set velocity at the end of each iteration of loop.

} while (RemTime > 0); //do loop while remaining time is greater than 0.

LCD.clear();

while (RemTime = 0) {

motor.disableOutputs();// after loop disable motor to save power

delay(500);

LCD.setCursor(0,0);

LCD.print("Complete!");

LCD.clear();

LCD.setCursor(0,1);

LCD.print("Please Reset");

delay(5000);

//wait for user to hit reset button

}

}