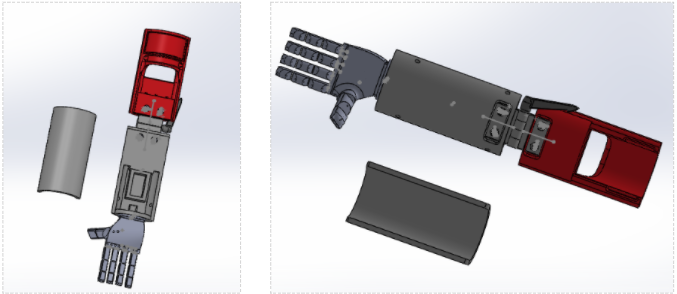

Complete Robotic Arm

3.0 Videos

Picking up a Water Bottle

Finger Functionality

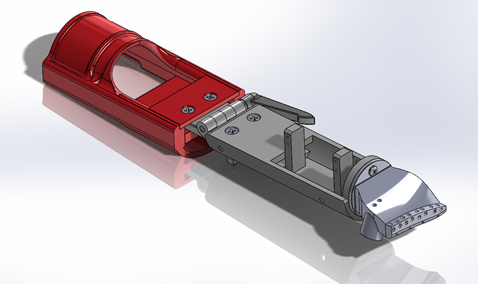

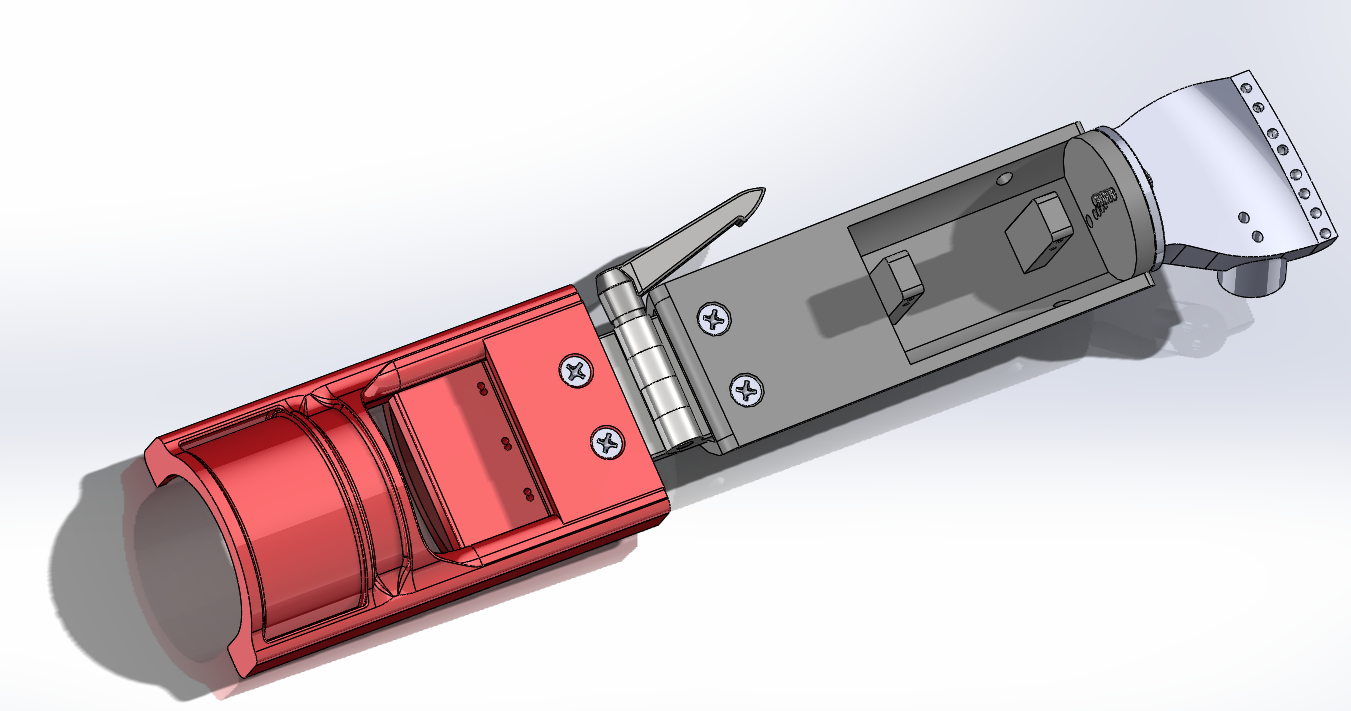

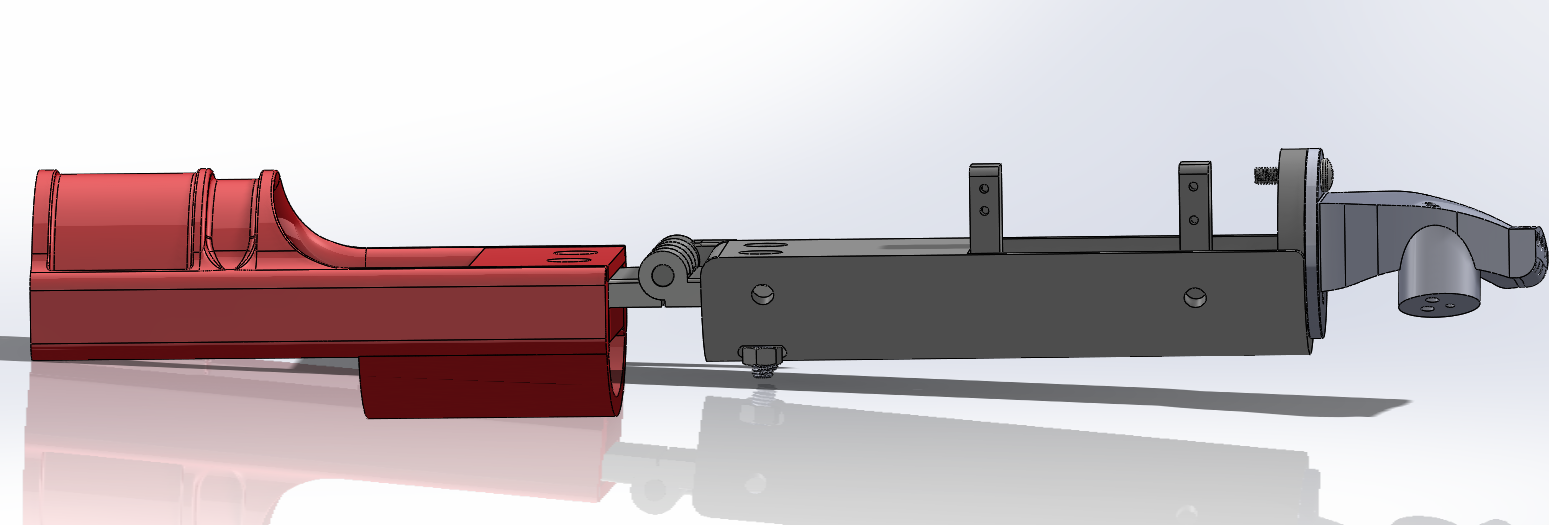

Solidworks Assembly Isometric View

Solidworks Assembly Back View

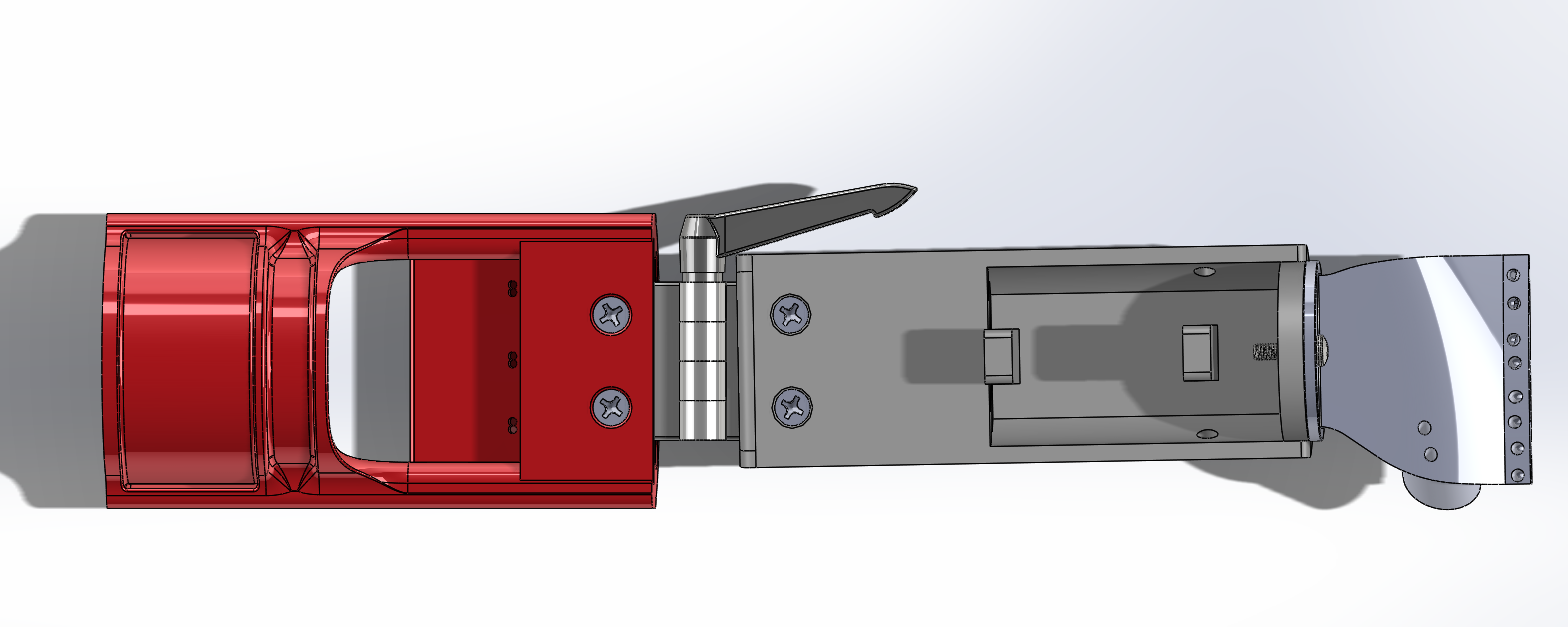

Solidoworks Top & Bottom View

Solidworks Assembly Side View

Solidworks Assembly Top View

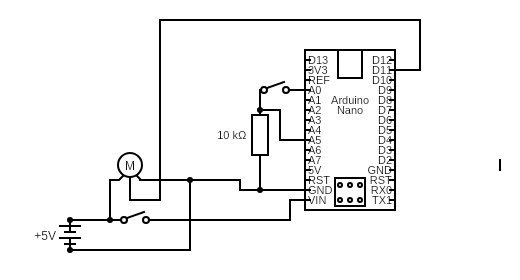

The circuit used in conjunction with the Arduino Nano utilizes

two switches, a pullup resistor, and a high-torque servo motor.

The first switch (Sw1) attaches power (9V [not 5V] battery)

to the Arduino and servo motor.

The second switch (Sw2) connects A0 (3.3V) to the pull-up resistor,

which inputs 3.3V (or a binary "1") to the nano.

This signals the Nano to turn the servo motor 180 degrees.

All grounds are common.

NOTE: This is an updated/simplified circuit from the origonal circuit I made (the one seen in the images).

#include

Servo myservo; // create servo object to control a servo

int flex = 0; // flex position (0 degrees)

int extend = 180; //extended position (180 degrees)

int servo = 9; //Servo on D11 (PWM pin)

int power = A0; //set A0 as 3.3V output

int go = A5; //A5 as input (goes from 0 to 1)

int state = 0; //state of activation (flexed vs. extended)

int delta = 0; //see if state has changed

int flexState = 0; //state variable to control if flexed or not

void setup() {

myservo.attach(servo); // attaches the servo on pin 11 to the servo object

pinMode(servo, OUTPUT); // sets servo pin as output

pinMode(power, OUTPUT); // sets A0 as output

pinMode(go, INPUT); // Sets A5 as discrete input

digitalWrite(power, HIGH); //write power pin to high always

myservo.write(extend); //ensure arm begins in extension

myservo.detach(); //detach while not in flexion saves battery power

}

void flexion() {

flexState = 1; //in flex state

myservo.attach(servo); //attach servo object. WIll draw current when attached

delay(100); //delay 100ms

myservo.write(flex); // tell servo to go to flex position (close hand)

delay(1000); //allow servo to travel to position (1000ms)

while (flexState == 1){ //loop to check if button has been pressed

state = digitalRead(go); //set "state" to state of the latch (0= open; 1= closed)

delay(100); //delay

delta = abs(digitalRead(go) - state); //check for a change in button state

if (delta > 0){ //if a change has occured

flexState = 0; //exit flexed state

delay(100); //delay

extension(); //enter extension function

}

}

}

void extension() {

delay(100); //delay 100ms

myservo.write(extend); //stretch fingers back out

delay(1000) ; //allow servo to travel (1000ms)

myservo.detach();

//detach so motor doesn't draw battery current in extension

// doesn't need torque since its not holding anything

}

void loop() {

state = digitalRead(go); //set "state" to state of the latch (0= open; 1= closed)

delay(100); //delay 100ms

delta = abs(digitalRead(go) - state);

//if button has been pressed (state has changed), close the hand:

if (delta > 0){ //if button is pressed (latch button)

flexion(); //call flex function

}

}